Power Generation Plant Fire Protection

Winnetka, IL

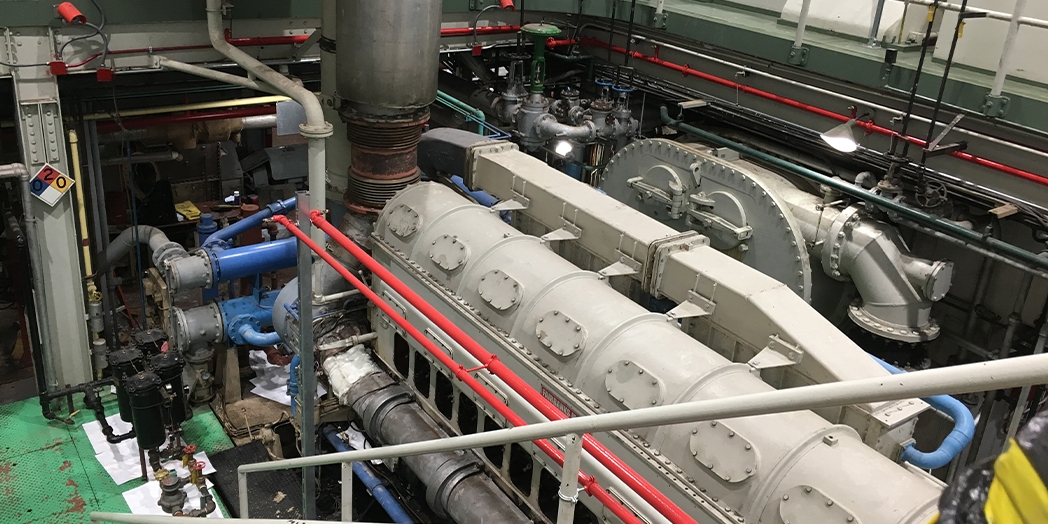

Clark Dietz provided fire protection and electrical design, and construction engineering services to add a new expandable fire protection system for the Village power generation plant. The plant currently utilizes natural gas fired steam boilers and three turbines along with two diesel generators to produce approximately 40 MW of power. In the preliminary stages of the project various other suppression options were considered for the plant including inert gas, water and nitrogen mist, hydro mist, and compressed air foam. Due to cost or other impacts it was decided that a water-based system was the best solution for the plant. The project included:

- Fully designed fire suppression system including preliminary head layout and pipe sizing.

- Extending new 10” fire protection service line for the building suppression system.

- New 2000 GPM/150 PSI fire pump along with jockey pump.

- New electrical service including new transformer and primary conduits.

- Dual power source issue was resolved by utilizing primary utility feed and Village power plant feed.

- The system was designed so the fire protection piping can be extended to the entire plant, including the exterior transformer yard.

- Interconnection of new fire protection system to existing alarm system.

- New CO2 suppression system for the turbine exciter bearings.

- Site work including cutting and patching of roadway, curb, relocation of hydrants and associated restoration for new service line.

- Replacement of two roof-top units, associated ductwork, three roof mounted make-up air units and exhaust fans, including patching and replacing affected roof areas.

- Design of a new fire pump room with two hour rated wall construction.

- Relocation of existing water utility mains within building to accommodate the new fire pump room.